Iridium and Platinum Catalysts for PEM Electrolyzers

Precious metal solutions around hydrogen generation with PEM water electolysis and other methods.

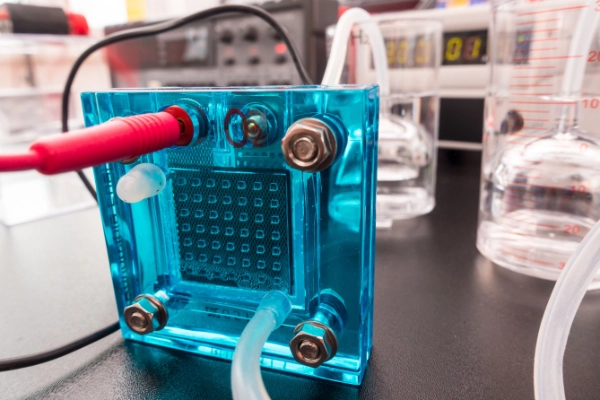

PEM Electrolysis: Catalysts for Electrodes

Alkaline and solid oxide electrolysis are two alternative technologies, whereas proton exchange membrane (PEM) electrolysis is increasingly gaining traction. It is expected that PEM electrolysis will play an important role in the transition towards a hydrogen economy.

Due to their excellent dynamic response time PEM electrolyzers are a perfect solution for storing curtailed, excessive renewable energy. Moreover, the advantage of high current density operation allows production of more Hydrogen from smaller set-ups compared to alkaline electrolysis. Due to the high-pressure outlet of hydrogen, PEM electrolyzer technologies are directly connectable to gas stations.

The production of green hydrogen through PEM electrolysis of water is a very suitable concept to enable storage, transportation and deployment of the produced renewable energy. Scale-up and cost reduction of green hydrogen represent the essential steps towards reducing the world´s carbon dioxide footprint.

PEM electrolyzer anode catalyst portfolio

The Heraeus’ product portfolio includes electrolyzer catalysts with different precious metal loadings. In order to find the perfect solution to your needs, we are able to test in our fully equipped on-site laboratories and test center.

In order to find the perfect solution to your needs, we are able to test in our fully equipped on-site laboratories and test center.

|

Catalyst |

Actydon | Ir 100 B | Actydon | Ir 80 X | Actydon | Ir 80 XSP | Actydon | Ir S | Actydon | Ir Ru |

|---|---|---|---|---|---|

| Features | High metal purity | High surface area |

Smaller agglomerate size for better processability |

High mass activity |

With stabilized Ru for high activity and Ir saving |

| Ir content [%] | 100 | 79 – 83 | 79 – 83 | 10 – 50 | 14 – 80 |

|

Ir crystallite size [nm] |

3 | 2 – 4 | 2 – 4 |

n.a. |

1.8 – 5.5 |

| BET surface area [m²/g] | >20 | >200 | >160 |

20 – 100 |

150 – 190 |

| Mass activity @ 1.45 Vcell (IR-free) [A/g] |

55 | 86 | 86 | 138 – 460 | 177 – 880 |

| online available | online available | Request More Information |

online available |

Request More Information |

Save 50–90% on Iridium compared to the market’s benchmark

We achieved breakthrough innovation by developing PEM electrolyzer catalysts with significantly reduced precious metal loading. Actydon | Ir S, low loading supported catalyst, will provide you with an up to three times higher catalyst performance while reducing the precious metal loading in the CCM by 50–90 % in comparison to earlier generations.

The latest Heraeus innovation is a ruthenium-based catalyst for PEM water electrolysis. Alongside iridium, ruthenium also catalyzes the Oxygen Evolution Reaction (OER), which is the critical part in PEM electrolysis. Ruthenium possesses superior catalytic activity to iridium but lacks stability in the challenging conditions of a PEM electrolyzer stack.

The Heraeus concept solves this problem by combining both ruthenium and iridium oxide in a novel manner, enhancing stability while maintaining the increased catalytic activity provided by ruthenium.

This ruthenium-iridium oxide material class delivers an unprecedented activity boost. The catalyst can achieve up to 50 times higher mass activity than iridium oxide, and unlike ruthenium oxide alone, it remains stable in operational conditions. Accelerated degradation tests confirmed its stability after 30,000 cycles, presenting activity loss significantly lower than for ruthenium oxide and on par with iridium oxide.

The implementation of low-lowding iridium electrolyzer catalysts will be an important factor for the hydrogen ramp up.

Iridium is a scarce metal, and the mining of primary material depends on the mining of platinum. Only about 9 tons of iridium are mined per year, and this amount is already in use in existing applications. Following the assumption that about 1.5 tons can be shifted to the hydrogen economy by using alternatives in other industries and tackling additional material streams in recycling, from 2025-2030 in total about 9 tons could be available.

On the other hand, globally 375GW of electrolyzer capacity has been announced until 2030. However, only a fraction of this announced capacities will in fact materialize until 2030, and again only a part of it with PEM technology. If we estimate that about one third of the announced capacities are really built and 35% thereof with PEM technology, we speak of around 40GW PEM electrolyzer capacity.

With current catalyst loadings of in average 400kg/GW, this would need 16 tons of iridium until 2030, more than most probably available (see above). With the reduced loading of 100kg/GW, which has been shown for the Heraeus next generation low-iridium catalysts (Möckl et al. JECS 2022), only 4 tons of iridium would be needed, which is in reach.

PEM electrolyzer cathode catalyst portfolio

The Heraeus’ product portfolio includes electrolyzer catalysts with different precious metal loadings. In order to find the perfect solution to your needs, we are able to test in our fully equipped on-site laboratories and test center.

| Catalyst | Actydon | Pt C240 | Actydon | Pt C700 | Actydon | Pt M700 |

|---|---|---|---|

| Description | 20 to 50 wt.% Pt on medium surface area carbon |

20 to 60 wt.% Pt on high surface area carbon |

40 to 50 wt.% stabilized Pt on high surface area carbon |

| Highlight | Highly accessible Pt particles | Optimized Pt surface utilization High ECSA | Improved Pt dissolution stability |

| ECSA [m²/gPt] | > 60 | > 70 | > 60 |

| online available | online available | Request More Information |

Your Expert for Catalysts for Electrodes

Platinum Precursors for Bipolar Plates

An electrolyzer is made up from many e.g. 50-150 electrolysis cells which form a stack. Between the cells of a stack, so called bipolar plates divide the individual cells from each other and transport the water and product gases to and from the membrane. As well, bipolar plates are conducting electricity and help to cool the system.

There are several alternatives for bipolar plate materials. However, if metals are chosen, the bipolar plates need to be coated with a precious metal e.g. platinum to protect the metal from corrosion. Due to the high electric voltage in the cells would otherwise start unwanted electrochemical processes that lead to oxidation and consequently to degradation of the bipolar plate. The coating prohibits degradation of material and helps to extend lifetime and performance.

Utilizing Platinum DNS, the bipolar plates are coated in an electroplating process with a thin platinum layer. Heraeus delivers Platinum DNS in proven quality according to your specific needs. Get in Touch.

2 Results

Color | Quotation | |||||||

|---|---|---|---|---|---|---|---|---|

| 5127022 | Platinum Dinitrosulfato | 12033-81-7 | Pt | 5,00 - 7,00 % | Pt(NO2)2(NH3)2•H2SO4 | Solution | Brown | Request a quote |

| 5137487 | Platinum Dinitrosulfato | 12033-81-7 | Pt | 1.80 - 1.85 | Pt(NO2)2H2SO4 | Solution | Brown | Request a quote |

While the platinum coating helps to increase the lifetime of the electrolyzer stack, at some point it will nevertheless reach the end of its lifetime. Close the loop by utilizing our best-in-class recycling services for PEM cells, which are capable to extract the precious metals from the CCMs.

Your Expert for Precursors for Bipolar Plates

Alkaline Water Electrolysis (AWE)

Most of the hydrogen that is produced today is coming from an Alkaline Water Electrolyzer (AWE). This technology has been around since decades and typically is not based on precious metals. In many cases it has been and still is the method of choice, while meanwhile some fields are emerging, where PEM electrolysis shows advantages, e.g. when it comes to high fluctuation of electrical input as typical especially for green energy.

As said, typically AWE is not involving precious metals. However, due to disturbances in the supply of some of the materials, including zirconia and nickel, also alternative materials are considered, some of them involving platinum group metals.

If you are interested exploring the contribution of possibilities for precious metals for AWE electrolysis our experts will be happy to assist.

Your Expert for Alkaline Water Electrolysis

High Temperature Electrolysis (SOEC)

In SOE (solid oxide electrolysis), an SOFC (solid oxide fuel cell) runs in reverse mode. Instead of using the fuel cell to generate electricity from hydrogen, a voltage is applied and water vapor is split into hydrogen and oxygen. The actual cell can therefore be used for both purposes: to generate hydrogen as well as to use the hydrogen later for electricity recovery.

Precious metals are rarely used in the SOEC (Solid Oxide Electrolyser Cell) or SOFC itself. However, they are often used in connection with industrial processes that generate waste heat, because the required high operating temperatures are then already available. In these processes, components containing precious metals are then often involved elsewhere.

For fuel processing Heraeus supplies catalytic solutions for Reforming, Water Gas Shift or Gas Purification e.g. by Preferential Oxidation (PROX) or Selective Methanation – all tailored to the needs of an independent decentralized system operation. Please see our gas purification page or on our solutions to a fuel cell operation for further HeraPur® purification technologies.

As with other types of electrolysis, the hydrogen can be easily purified from unwanted components in SOE. You can find out more about this under Hydrogen Purification.

Your Expert for High Temperature Electrolysis (SOEC)

Read As Well