Hydrogen Consumption

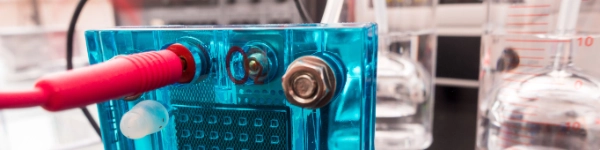

Proton exchange membrane (PEM) fuel cells convert hydrogen and oxygen into water and thereby release energy. The heart of a fuel cell is a polymer electrolyte membrane coated with platinum-based catalysts on both sides (catalyst coated membrane, CCM).

Catalysts for PEM Fuel Cells

PEM fuel cells can be used in different mobile and stationary applications, such as power storage, material handling vehicles, light-duty and heavy-duty transport. Within the transportation sector fuel cell electric vehicles partially compete with battery electric vehicles. However, the characteristics of higher driving range and significantly lower refueling times make hydrogen fuel cell vehicles the technology of choice for long range and heavy-duty transportation.

Due to the collective commitment to the mission of reducing carbon dioxide emissions, and creating a climate neutral society, the growth of PEM fuel cells is widely foreseen. This will enable worldwide deployment of fuel cell electric vehicles and significant reduction of costs for those.

Heraeus offers precious metal-based catalysts for the cathode and the anode side of CCM for a variety of fuel cell applications, including:

- Stationary

- Material handling vehicles

- Passenger cars

- Heavy-duty transport

- Trains and buses

Heraeus’ PEM Fuel Cell Catalyst Portfolio

In a PEM fuel cell Heraeus platinum-based catalysts help to boost both electrode reactions in a fuel cell stack to form water and generate energy from H2 and O2 at various conditions on high efficiency.

Our product portfolio includes PEM fuel cell catalysts with different precious metal loadings.

In order to find the perfect solution to your needs, we are able to test in our fully equipped on-site laboratories and test center.

| Catalyst | Actydon | Pt C100 + Actydon | Ir 80 X |

Actydon | Pt C240 | Actydon | Pt C700 | Actydon | Pt M700 | Actydon | Pt 50 K700 |

|---|---|---|---|---|---|

| Description | 20 to 40 wt.% Pt on graphitized carbon material – optional with OER additive for even higher CRT |

20 to 50 wt.% Pt on medium surface area carbon |

20 to 60 wt.% Pt on high surface area carbon |

40 to 50 wt.% stabilized Pt on high surface area carbon |

50 wt.% PtCo on high surface area carbon |

| Highlight | High cell reversal tolerance >8000 s (15 μg Ir /cm²) (~75 s w/o OER additive)** | Highly accessible Pt particles | Optimized Pt surface utilization High ECSA | Improved Pt dissolution stability | Higher Pt-dissolution stability compared to established PtCo/C catalyst |

| ECSA [m²/gPt] | > 40 | > 60 | > 70 | > 60 | > 45 |

| Cell voltage @ 0.1 A/cm² (CCM)* [V] |

~ 0.80 | ~ 0.84 | ~ 0.84 | ~ 0.84 | ~ 0.84*** |

| Request More Information | online available | online available | Request More Information | Request More Information |

*Automotive conditions **Cell reversal tolerance time until -1.25 Vcell ***At 0,2mgpt/cm2

Your Expert for Cataysts for PEM Fuel Cells

Precursors for Coating of Bipolar Plates

In fuel cells stacks, bipolar plates are used for the gas separation between the adjacent cells, but at the same time they are also cooling and sealing the cell to the outside. Functionally, they distribute the gases and water to and from the anode and cathode and provide the electrical connection. Between the bipolar plates the membrane electrode unites are arranged.

Among several material possibilities, metallic bipolar plates are used to save weight and volume, but also because they offer advantages in the starting behavior of the fuel cell. However, bipolar plates need excellent electrical conductivity, which does not decrease significantly even during the electrochemical processes in the fuel cell. Therefore, if consisting of metal, bipolar plates need a corrosion protection to avoid oxidation. Oxidation would also lead to porosity, disturbing the transporting capability of gases and water.

To protect the metal substrate, a thin platinum layer is deposited on the bipolar plate by electroplating. Platinum DNS is utilized in an acidic electroplating bath, resulting in a thin and robust platinum layer.

Your Expert for Precursors for Coating of Bipolar Plates

Catalytic Solutions to Boost the Fuel Cell Operation - Balance of Plant

Fuel cells that convert the chemical energy of a fuel and an oxidant directly into electricity, are a key technology in the energy transition – especially as a sustainable decentralized power source.

A variety of different fuel cell technologies exists, characterized for example by their operating principle, the applied electrolyte, their operating temperature or the fuel in use. As varied as the fuel cell technologies themselves are the demands placed on the supporting equipment that enables the cell to function as an environmentally friendly and reliable energy source in the first place.

Beyond our own fuel cell catalysts for PEM electrolysers Heraeus Precious Metals meets these challenges with its efficient catalyst technologies to gas treatment and emission reduction.

For fuel processing Heraeus supplies catalytic solutions for Reforming, Water Gas Shift or Gas Purification e.g. by Preferential Oxidation (PROX) or Selective Methanation – all tailored to the needs of an independent decentralized system operation. Find more details about the Heraeus heterogeneous catalysts in the catalyst selector.

Our long-term experience in emission catalysis at Heraeus Precious Metals enables us to produce efficient and durable and catalysts for your off-gas treatment and a possible energy recovery by catalytic combustion.

Each fuel cell technology has its individual advantages and constraints which eventually define the applications for which a technology is most suitable. Heraeus Precious Metals will support you with our bulk catalysts and tailored catalytic coatings to best adapt the balance of plant to your individual mission.

Your Expert for Catalytic Solutions to Boost Fuel Cell Operation

Read As Well