Recycling of Critical Raw Materials for a Circular Hydrogen Economy

Regain scarce and valuable assets from production scrap and end-of-life materials: Recycling of platinum, iridium, ruthenium and palladium as well as ionomers from the Catalyst Coated Membrane (CCM).

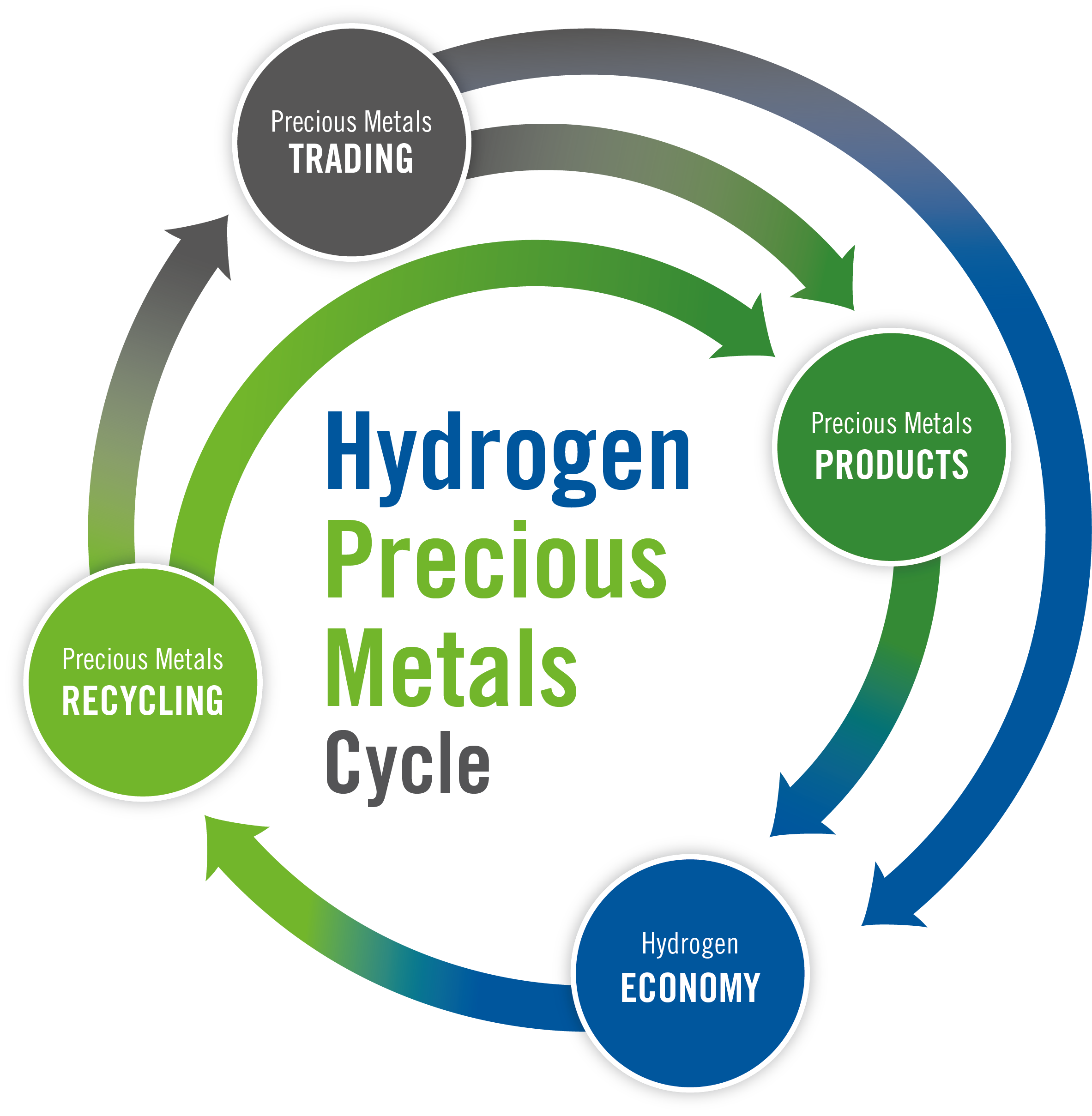

Precious Metal Recycling Integral in the Value Chain of the Hydrogen Economy

Platinum group metals play an important role along the hydrogen value chain and are used in various areas. As the global demand for these valuable metals from many industries is higher than the annual production, it is essential to recycle metal residues from production and materials at the end of their life cycle.

Heraeus Precious Metals is one of the largest recyclers and refiners of precious metals with more than 90 years of recycling experience and twelve facilities in seven countries (USA, Germany, Switzerland, South Africa, India, China, Canada). Heraeus continues to invest in additional capacities to support the hydrogen economy.

In the long term, recycling capacities are an indispensable part of the hydrogen economy. Iridium in particular must be recovered in order to equip the electrolyzers with new CCMs at the end of their service life.

In addition to the economic and resource-related necessity of recovering the precious metals, recycling is also of great ecological importance. In fact, the CO2 footprint of recycled precious metals is up to 99% lower than that of metals from the primary industry. Heraeus Precious Metals is setting ambitious targets to increase the use of recycled precious metals in its products and will be the world's first carbon-neutral (scope 1+2) precious metals company by 2025.

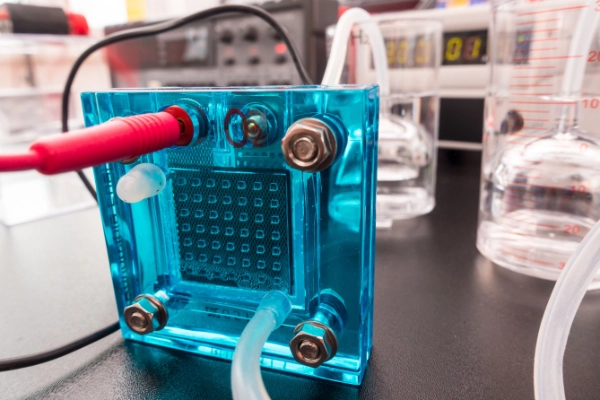

Heraeus is one of the biggest platinum group metals (PGM) refiners in the world having more than a decade of experience in the hydrogen environment: Recycling of components and materials from electrolyser and fuel cell stacks such as Membrane Electrode Assemblies (MEAs), CCMs, bipolar plates, Porous Transport Layers (PTLs) as well as production scrap and spent catalysts from gas purification.

Today, all steps of a modern hydrometallurgical process for platinum, iridium, ruthenium and palladium are available. This includes the preparation, sampling, analysis and refinement of precious metals. Driven from the new demand in the markets, the technology is developed further to industrialize and open new possibilities.

After recycling, customers benefit from maximum flexibility. The regained metal is credited to their precious metal pool account, where it can be accessed and managed around the clock via the customer platform myHeraeus.com. It can be used directly for the production of a new Heraeus product to avoid potential metal price risks, e.g. for a new electrocatalyst or a precursor for a coating. It can also be sold to Heraeus and turned into cash, or it can be physically provided to any destination in the world.

Materials Processed by Precious Metal

| Material |

Au |

Ir |

Pt |

Pd |

Ru |

|---|---|---|---|---|---|

|

Electrodes |

• |

• |

• |

• |

|

|

MEAs / CCMs |

• |

• |

• |

• |

|

|

Bipolar Plates, PTLs, etc. |

• |

• |

• |

• |

• |

|

Catalyst Inks / Pastes / Coatings |

|

• |

• |

• |

• |

|

Spent Electrocatalysts |

• |

• |

• |

• |

|

| Floor Sweeps, Wipes, Washes, etc. |

• |

• |

• |

• |

Actydon | Loop Stack:

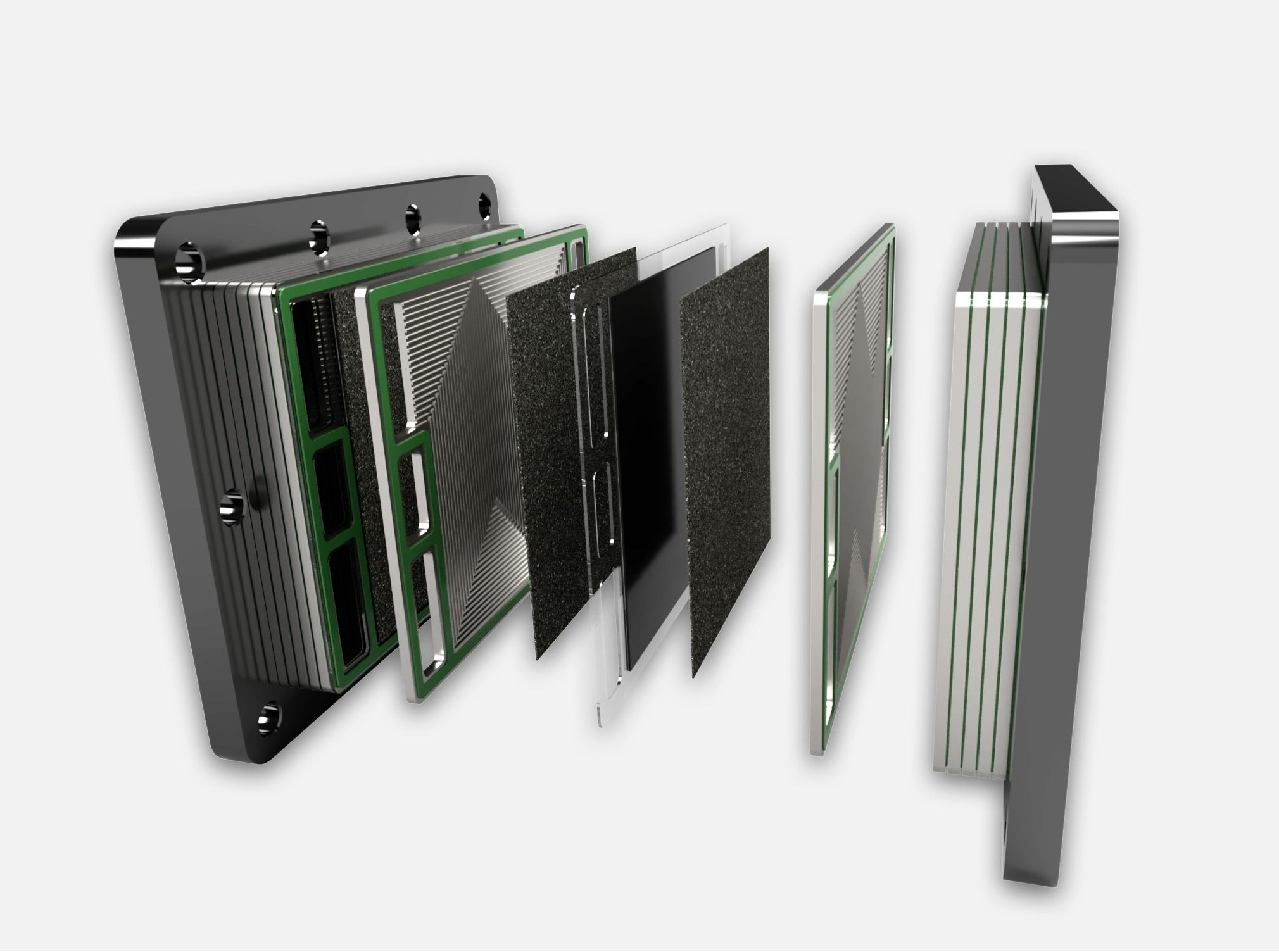

The Hydrogen Recycling Loop for Electrolyzer and Fuel Cell Stacks

The Hydrogen Recycling Loop for Electrolyzer and Fuel Cell Stacks

Stack Recycling: Heraeus is maximizing the return of all valuable parts from electrolyzer and fuel cell stacks, such as MEAs, CCMs and bipolar plates.

Would you like to return entire stacks?

Specializing in end-of-life recovery, Heraeus expertly reclaims precious metals from your MEA, CCM and bipolar plate components. The proven and efficient process ensures that iridium, platinum, ruthenium and other valuable materials are sustainably recycled. Heraeus will maximize the re-use of secondary raw materials.

Heraeus has taken significant steps to invest in capacities to support the growing hydrogen economy with state-of-the-art recycling facilities that are able to manage these requirements in a sustainable and environmentally friendly way.

As production increases however, besides these end-of-life materials, the recycling from production scrap will become more important – and not only precious metal recycling but also regaining of other valuable materials like the membranes itself get in the focus.

Actydon | Loop MEA

Recycling Ionomer Membranes: Fluoropolymers

The establishment of a circular economy in hydrogen technologies, is essential, and this is not limited to precious metals. There are also non-precious metal-bearing materials, such as ionomer membranes, which are high-value technology products that require considerable investment, energy and effort to manufacture.

Heraeus Precious Metals is actively researching methods and optimization of processes to establish and promote this material cycle. A chemical process that separates precious metal contents from the membrane material and recovers the ionomers has been successfully demonstrated. Together with partners, research is ongoing to further develop the process and to transfer it to scale. If you are able to offer specific know how to contribute to this exciting journey, don't hesitate to get in touch. Heraeus is also interested in collaborating with new partners on ionomer recycling.

The initial focus in ionomer recycling is forecasted to lean to production scrap. It will still take quite a while until end-of-life material is expected to be due for recycling, as significant capacities first need to be built up and then run for at least 12 years. Secondly, the production scrap is more suitable for a first attempt as it offers significant advantages. The ionomers, have a long life, 12 years or more of intensive use in hydrogen applications, they will exhibit a more homogenous quality. With time, processes will be optimized and experience will expand. When it comes time to treat end-of-life materials both processes and the market applications for the recycled materials will be more developed and mature.

Actydon | Loop Scrap

Recycling of Production and Manufacturing Scrap

To recover valuable precious metals from hydrogen applications, there is no need to wait until electrolyzers and fuel cell stacks have reached the end of their life. Waste such as spent electrocatalysts, catalyst inks, pastes, coatings, floor sweeps, wipes or washes are already generated during the manufacturing process of MEAs, CCMs and bipolar plates.

Even if the precious metal residues are significantly lower compared to EOL material, Heraeus is also able to economically recover so-called low-grade material for manufacturers of hydrogen applications thanks to special recycling processes with state-of-the-art equipment.

Speak to the Heraeus recycling experts now to plan for the recovery from production scrap and later the end-of-life materials to support your future hydrogen projects.

Read as Well

Get in Touch With Us