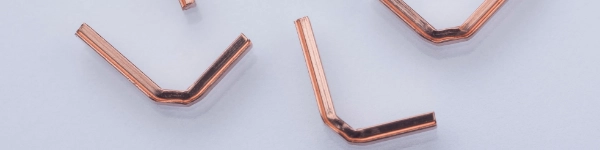

Commutator Angles and Brushes

In many electronic systems, signals or currents must be transmitted without a fixed connection between the clip and the signal transmitter.

About Commutator Angles and Brushes

Sliding contacts are used to transmit the electricity (commutator brushes and commutator angles, e.g. in DC motors). Using a solution such as this, signals can also be transmitted with greater stability and less noise interference.

Such a commutation system can be installed in an extremely small space, such as in motors of 10 mm in diameter. Speeds can easily reach 15,000 rpm.

The material is decisive for the functionality and service life of sliding contacts like these. Brushes, for instance, need very good elastic properties, low contact resistance, and often also have to be reliable in aggressive environments and work without failure.

By combining properties of different materials (graphite, precious metal, non-precious metal), we provide brush contacts with precisely the properties that our customers require. In these composites, Heraeus combines the best properties of non-precious (e.g. elastic properties) and precious metals (e.g. conductivity, abrasion resistance, resistance to corrosion) for optimal functionality in your application.

Get Advice on Your Specific Requirements

Contact us to discuss further steps to find the optimal solution for your process.

Find the optimal electrical contact tailored to your application needs – from roll clad materials to sliding contacts to silver contact materials.

Advantages

We look forward to finding the right solution for your application. Form and design can be determined individually.

- The precious metal wipers can be adapted specifically to your requirements

- We offer a great deal of flexibility with regard to the selection of materials

- You achieve dependable transmission of commutation currents and good signal transmission and stability, minimal signal noise, and low contact resistances

- Commutator systems with precious metal have a low risk of failure in aggressive environments

- Through the combination of the best properties of different materials, our sliding contacts feature long service life and reliability

Applications

Precious metal wipers for brushed motors are used primarily in applications requiring reliable transmission in a very small space.

They are found in electronic commutation systems in DC motors. These precision motors are used in industrial and medical technology, in pick-and-place machines, in medical robots, or as seat adjustors in aircraft, just to name a few.

Product Properties & Technical Data

Spring material (brush)

- CuBe

Contact material

- Hera 174 (PtIr alloy)

- Hera 238 (AuAgCu alloy)

- Hera 614 (PdCu alloy)

Collector material

- AgCu alloy

- AgNi alloy

- AuAgCu alloy

- PdAgCu alloy