Recycling Anodes

Reclaiming residual iridium from spent and obsolete anodes is not easy, however due to the scarcity and high value of iridium it is always worthwhile. Utilizing advanced technology, Heraeus Precious Metals sets a global standard in the sustainable recovery of iridium from mixed metal oxide (MMO) coatings. Customers find a simple process ready to use in their recoating or scrapping routine, which creates a circular economy and increased sustainability to the global PGMs markets.

Following years of research and dedication have resulted in a state-of-the-art process to facilitate the recovery and recycling of platinum group metals (PGMs) from spent mixed metal oxide (MMO) electrodes. Effectively creating value from waste is actively increasing sustainability in global PGMs markets.

Recycled and Treated Materials - What Applications are Suitable?

Anodes 101

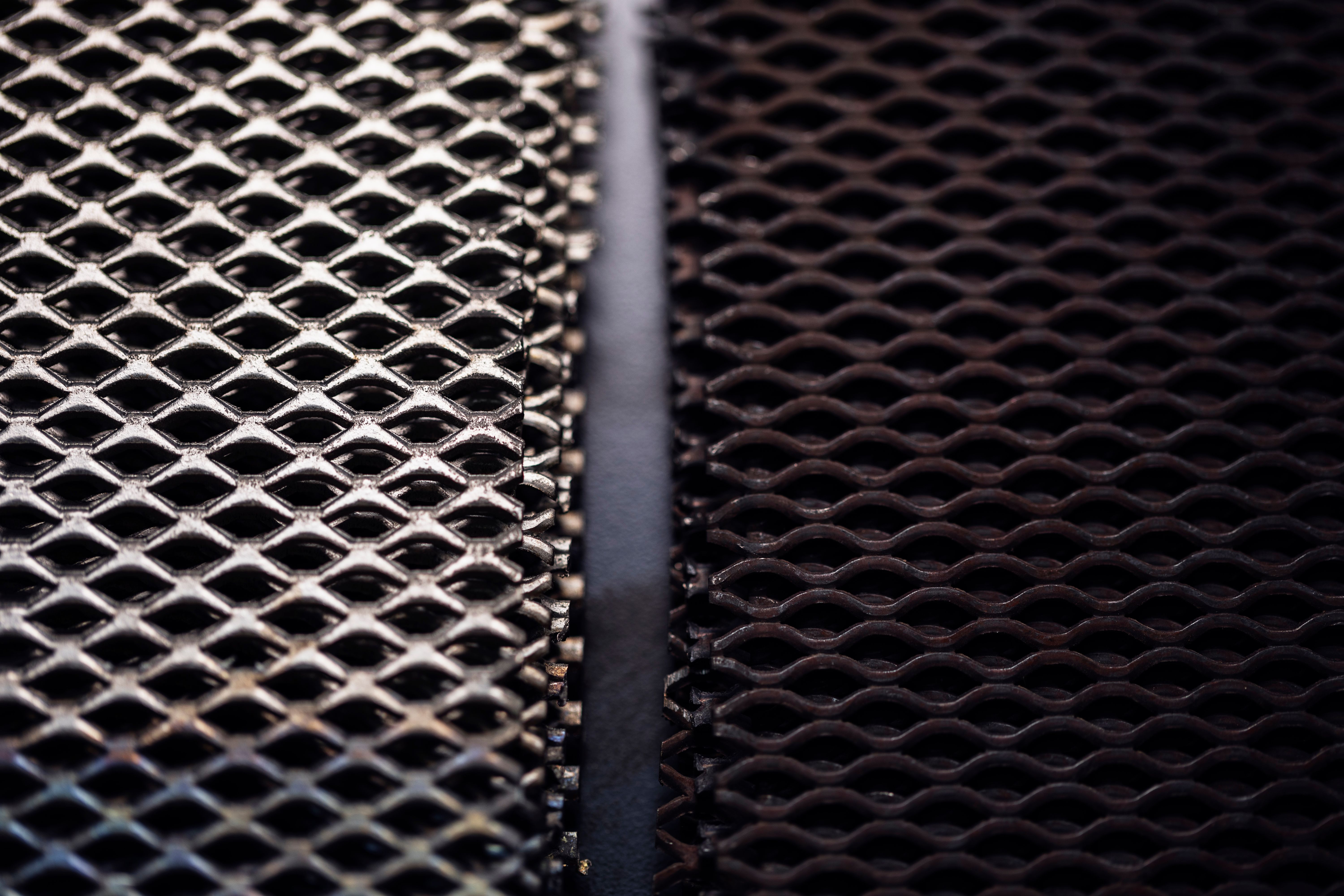

Mixed metal oxide electrodes, also known as Dimensionally Stable Anodes (DSA), are highly conductive and corrosion-resistant anodes used in electrolysis.

These anodes consist of a titanium substrate, such as a plate or expanded mesh, coated with metal oxides like RuO₂, IrO₂, or PtO₂. These oxides not only conduct electricity but also act as catalysts for reactions, such as chlorine gas production.

Each substrate is typically coated with around 10 to 12 grams of precious metals per square meter.

Recovery Applications

Heraeus treats materials that are typically (but not exclusively) used in:

- Electro Tinning

- Electo Galvanizing

- Metal Electroplating

- Electrowinning of Base Metals

- Copper Foil Production

- Industrial Water Treatment

- Chlor Alkali for Production of Caustic Soda and Chlorine

Your Benefits of Partnering With Us

Your and our goal is to create and foster relationships that ensure shared success.

Enjoy working with a highly experienced and professional partner.

-

Global Sales Team

-

Delivering high-quality, refinery-ready product

-

Low production costs and rapid turnaround times

-

Comprehensive quality assurance

-

Eco-efficent processing

Exploring Collaboration - The Service Offering for You

End-of-life Anodes

Recycling of anodes containing precious metals and credit them to you.

Benefit from a up to 95% recovery rate of residual PGMs.

Precious Metals Content Analysis

Ability to accurately measure residual loadings on anodes based on samples.

Refurbishment: Cleaning of Anodes for Recoating

You receive a clean substrate for recoating. Achieve the increased substrate longevity with improved surface prep